The drawing block or multiple drawing system forms the heart of every concrete reinforcing steel wire line. We use cold rolling tools instead of drawing dies to enable high efficiency, which are also supported by the following automated wire handling systems.

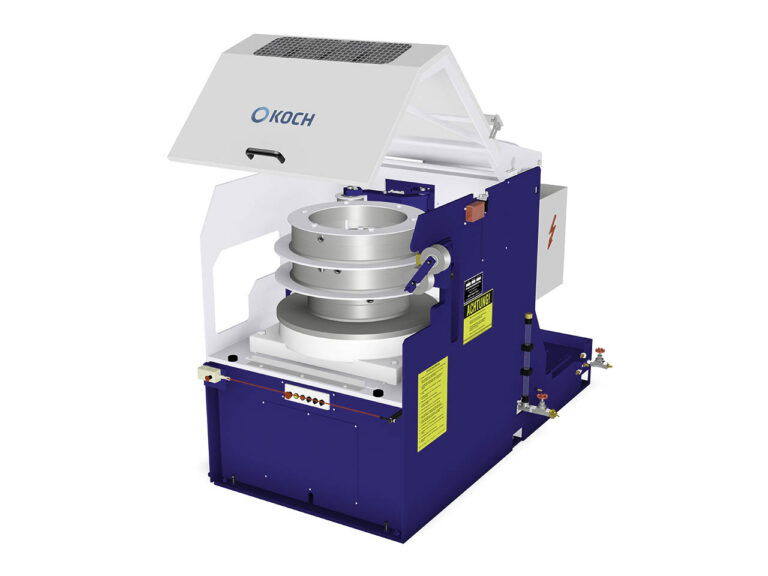

Vertical drawing machine with single or double draft.

Inlet dia. lc (mm): 5.5-16.0

Finish dia. lc (mm): 4.0-14.0

Capstan dia. (mm): 700

Pulling power (N): 50,000

Drive power (kW): 132-max. 200

Drawing speed (m/s): max. 12.0

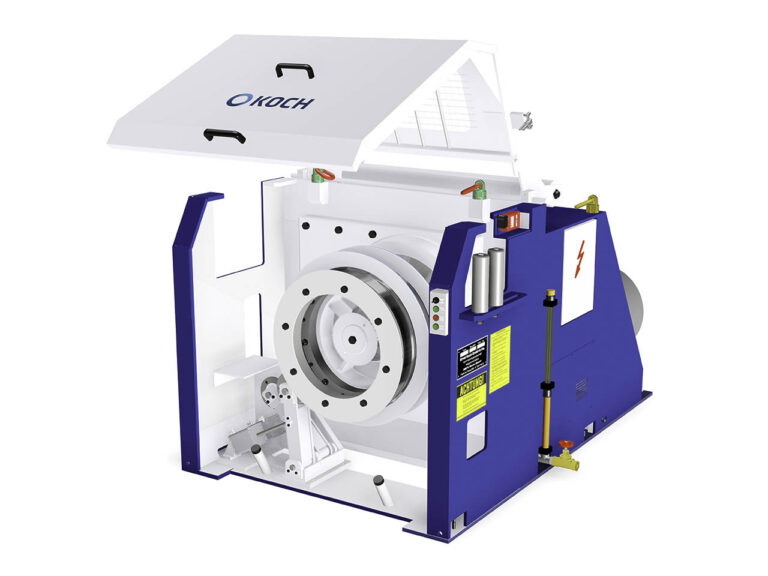

Horizontal drawing machine with single or double draft.

Inlet dia. lc (mm): 5.5-16.0

Finish dia. lc (mm): 4.0-14.0

Capstan dia. (mm): 700

Pulling power (N): 50,000

Drive power (kW): 132-max. 200

Drawing speed (m/s): max. 12.0

System for continuous stretching of hot rolled material, Machine frame of MSH profile. Noise suppressive machine house with connection for fine dust extraction, consisting of 4 rigidly fitted support rolls and 3 water cooled bending rolls, adjustable by means of screw jacks. Support and bending rolls are equipped with quick -change tungsten carbide rings. Greasing of all rolls via central greasing unit.

Inlet dia. lc (mm) :6.0-16.0

Drawing speed (m/s): max. 10.0

V-shape capstan dia. 800 mm, V-shape pulleys, C60 material, flame-hardened, mounted with hub straight onto gear shafts, guiding rolls and guiding rails of tungsten carbide , wire-break switch by means of ring sensor.

Inlet dia. lc (mm): 6.0-16.0

Drive power (kW): 160-max. 250

Drawing speed (m/s): max. 10.0

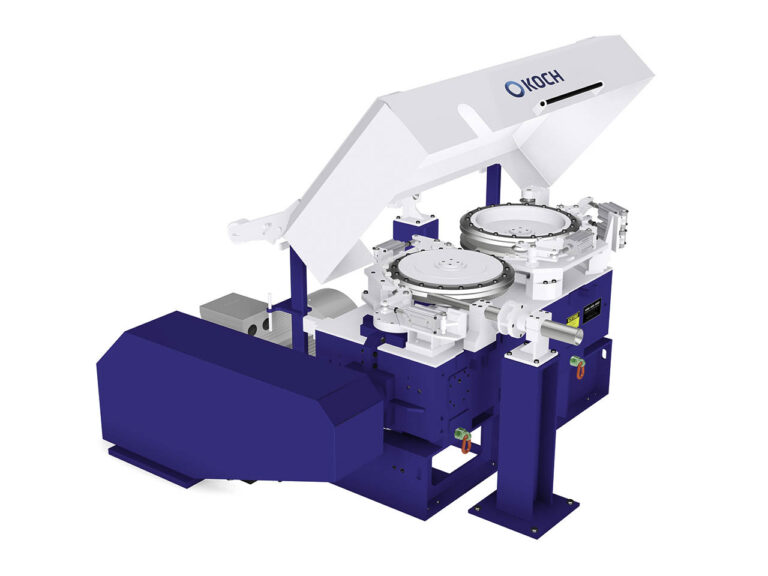

Spoolers work in combination with wire drawing machines and are used to take-up drawing wires onto rigid or automatic spools.

Finish dia. lc (mm): 4.0-14.0

Drive power (kW): 37-45

Drawing speed (m/s): max. 10.0

Dia. of spool flange (mm): 3000

Spoolers work in combination with wire drawing machines and are used to take-up drawing wires onto rigid or automatic spools.

Finish dia. lc (mm): 4.0-14.0

Drive power (kW): 37-45

Drawing speed (m/s): max. 10.0

Dia. of spool flange (mm): 5000

Spoolers work in combination with wire drawing machines and are used to take-up drawing wires onto rigid or automatic spools.

Finish dia. lc (mm): 4.0-14.0

Drive power (kW): 37-45

Drawing speed (m/s): max. 10.0

Dia. of spool flange (mm): 3000

Spoolers work in combination with wire drawing machines and are used to take-up drawing wires onto rigid or automatic spools.

Finish dia. lc (mm) 4.0-14.0

Drive power (kW) 37-45

Drawing speed (m/s) max. 10.0

Dia. of spool flange (mm) 5000

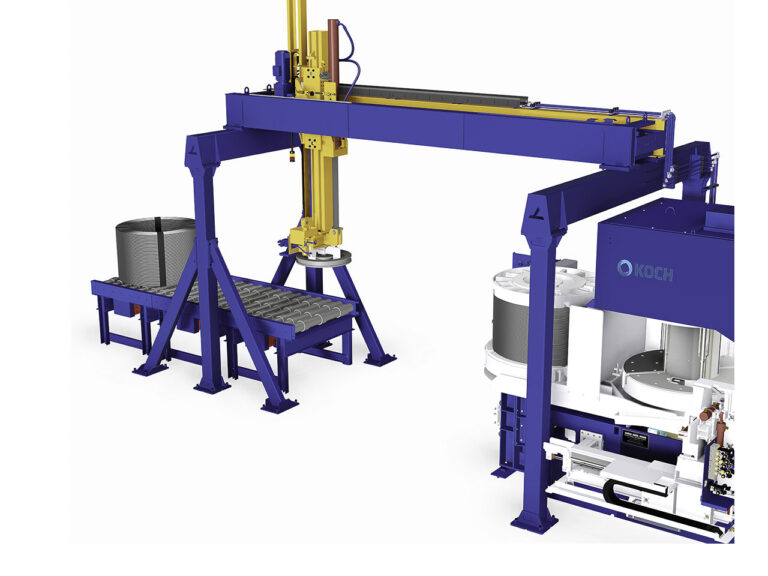

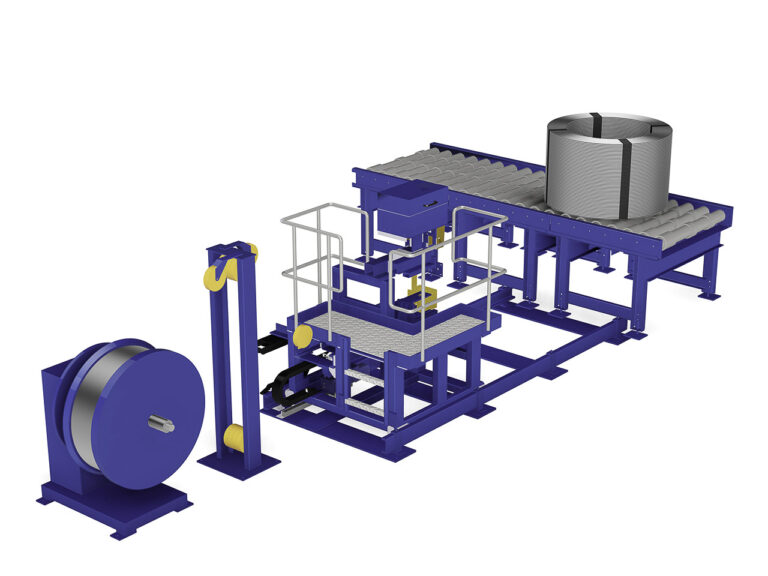

Coil discharging systems in reinforcing steel lines serve to a fully automatic discharge of finished coils. The column type swilling system offers the possibility of discharging two parallelly installed lines with one system.

Drawing speed (m/s): max. 0.5

Linear systems in reinforcing steel lines serve to a fully automatic discharge of finished coils. The travel movement of the system is linear. One system is provided for each production line and bears the advantage compared to the swilling type that dead times due to production are avoided. The installation is on floor, a separate foundation is not required.

Drawing speed (m/s): max. 0.5

Automatic strapping system.

Standard wire feeding device to wire drawing machine.

Finish dia. lc (mm): 6.0 – 18.0